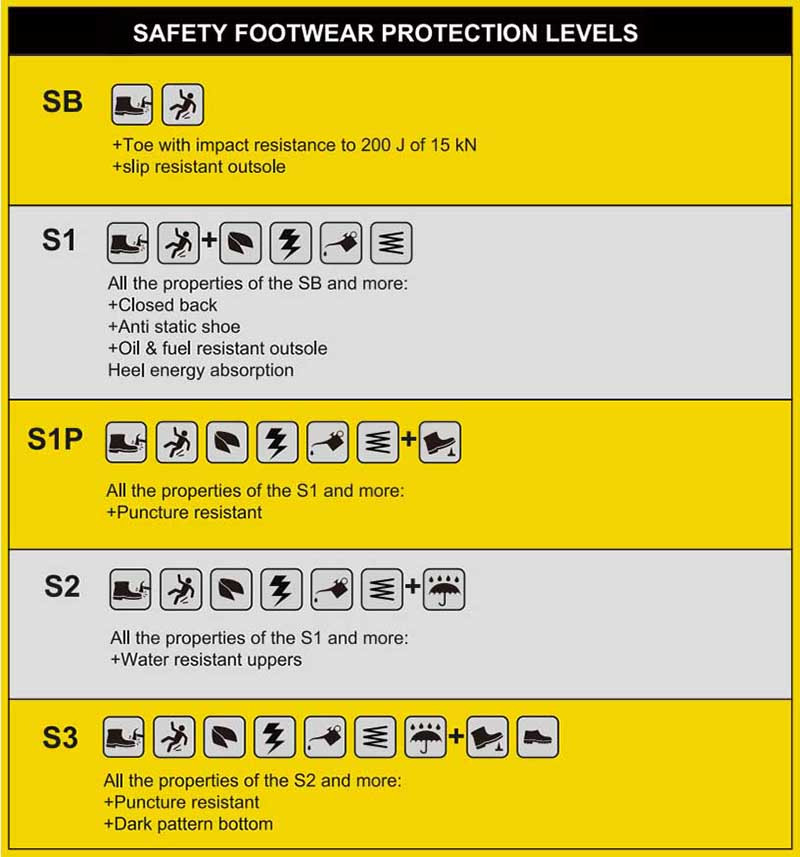

Safety footwear EN ISO 20345:2011

SB:Basic requirements for shoes and impact resistance of toecaps 200Joule

S1:SB+Additional requirements:

– Closed seat region

– Antistatic properties

– Energy absorption of seat region

– Fuel resistance

S1P:S1+Additional requirements:

– Puncture Resistant

S2:S1+Additional requirements:

Water penetration and absorption

S3:S2+Additional requirements:

– Penetration resistance

– Cleated outsole

S4:Anti-smashing, anti-static, anti-oil, back closure, heel absorption

S5:S4+Additional requirements:

puncture resistance

S6:S2+Additional requirements:

Water resistance

S7:S3+Additional requirements:

Water resistance

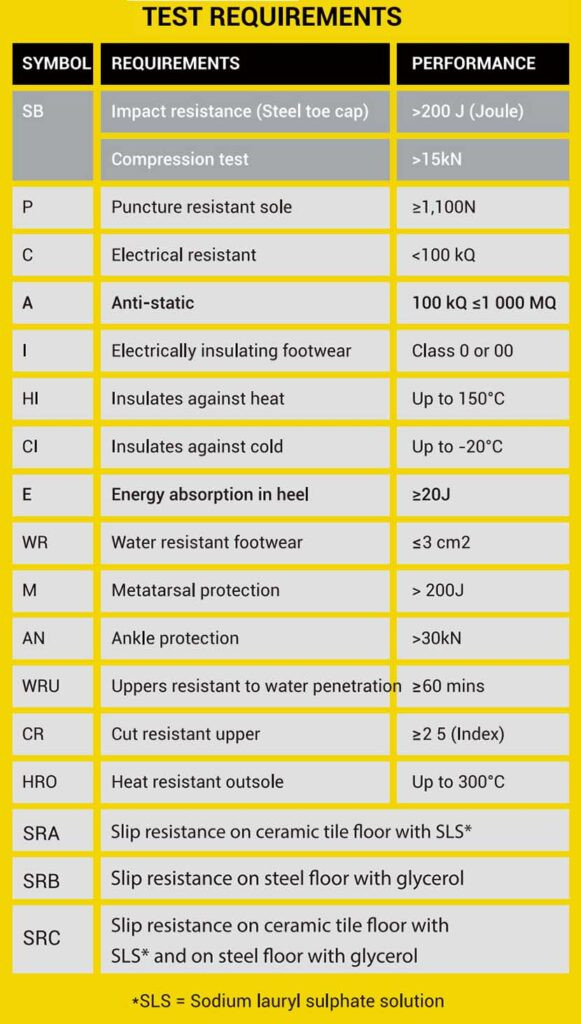

HRO:Heat resistant to 300℃ for 1 minute, no melting or cracking of the sole

WR:At the height of the upper, bend the shoes repeatedly for 80 minutes in the water,and the wetted area inside the shoe ≤3cm

HI:

Heat-resistant 150℃, lasts 30 minutes,the temperature rise inside the shoe does not exceed 22℃

CI:

Low temperature resistance to -17℃, lasts 30 minutes,the temperature drop inside the shoe does not exceed 10℃

SRA:

Use soap liquid test on glazed tiles, pressure 400-500N, friction coefficient ≥0.28

SRB:

Use glycerin test on stainless steel plate, pressure 400-500N, friction coefficient ≥0.13

SRC:

SRA+SRB test passed at the same time, MKsafety are SRC unless otherwise specified